Water is an amazing resource! We all know that we need to drink water to survive, but did you know that humans have been using the power of water to do work or generate electricity for thousands of years?

Water power through the ages

The Roman Empire used the power of water extensively in the first century BCE (before common era). It is known that the Greeks used water wheels to grind flour more than 2,000 years ago. There is evidence that water wheels were also used in China, and the French are responsible for creating one of the first hydropower turbines in the mid-1700s.

Over the last 100 years, hydropower has advanced considerably and is one of the most popular forms of renewable energy generation today.

Read on to find out more about the power of water.

Water wheels

Water wheels are machines that use the energy of flowing or falling water (or both) to turn a wheel. The axle of the turning wheel can then power other machines to do work.

Water wheels were used throughout Europe during the Middle Ages (approximately 500 to 1500), as the main source of power for driving large machines. Some examples of how water wheels were used are:

- driving the mills that ground grain into flour

- moving bellows (air blowers) used in metal foundries in the iron smelting process

- hammering flax leaves to make paper

- crushing rock (often used to make roads).

How water wheels work

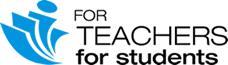

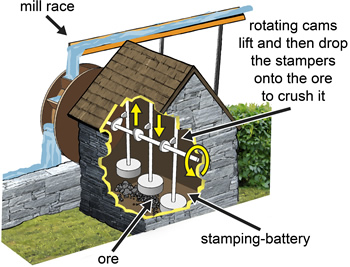

Water wheels have several important parts that work together (see diagram).

- Flowing water (delivered via a channel called a mill race)

- Large wooden or metal wheels

- Paddles or buckets (arranged evenly around the wheel)

- Axle

- Belts or gears

To produce power, the energy of flowing water pushes against the paddles or buckets and turns the wheel. This causes the axle to turn which drives belts and gears that power the machinery. The larger the diameter of the wheel, the greater ‘leverage’ and so the greater turning effect on the axle that drives the machine. The mill race has two parts: the part that brings the water to the wheel is called the ‘head race’ and the part that carries the water away is the ‘tail race’.

Water wheel designs

Water wheels can be horizontal or vertical, but the vertical design is more common and much more efficient. There are two common vertical water wheel designs: ‘undershot’ and ‘overshot’.

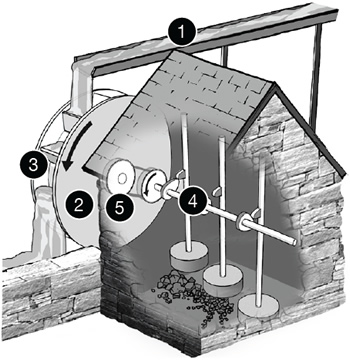

Undershot water wheels

An undershot wheel is mounted above the mill race with the bottom of the wheel in the water. The flowing water strikes the paddles or blades and turns the wheel. The faster the water is flowing the faster the wheel will turn.

Overshot water wheels

In an overshot water wheel, the mill race brings the water to the top of the wheel, where it strikes the paddles or buckets and turns the wheel. This is more efficient because as well as the force of the flowing water, the weight of the falling water helps to turn the wheel. This is a benefit of this design as it will still work even when the flow of water is not very fast.

Surviving water wheels

The Beaconsfield Gold and Heritage Museum (Grubb Shaft) in Tasmania has a working overshot water wheel that drives a huge stamping-battery machine that was used to crush the quartz ore containing gold. The machine was built in 1862 and still works!

Another fine Australian example is the Bridgewater Mill in South Australia built by John Dunn in 1859. This was originally a flour mill and is still preserved today as a restaurant and tourist destination. This is an example of a ‘backshot wheel’, a version of the overshot water wheel where the water from the race is introduced just behind the top of the wheel.

Hydroelectric dams

In recent times, the principles of hydropower have been revived through water-powered turbines which use the energy of water flowing down a slope to generate hydroelectricity.

How hydroelectric dams work

Hydroelectric dam systems generally have three parts:

- an electric plant or substation where electricity is produced

- a dam that can be opened or closed

- a reservoir where water can be stored.

Hydroelectric dam systems generate power when the water that has been stored in the dam is released into a pipeline and flows over a turbine. The force of the water causes the turbine to spin, which operates a generator. The generator produces electricity which is transferred to a substation and then into a grid. Excess water is released back into a waterway.

Hydroelectricity in Australia

The Snowy Mountains Hydroelectric Scheme (the Scheme) in New South Wales is recognised as an engineering wonder. It took thousands of people 25 years to build, and when it was finished, it included seven power stations, 16 dams and 225 kilometres of pipeline.

At first, the Scheme was going to be for irrigation, but the designers knew it had potential to generate electricity too. The government was able to pay for this huge structure through the money it earnt from selling the electricity. The Scheme diverts water from the Snowy, Eucumbene and Murrumbidgee rivers westward through the Great Dividing Range and then releases water into the Murray and Murrumbidgee rivers.

Tasmania also has a huge network of hydroelectric dams that are now the largest generator of renewable energy in Australia.

Hydropower accounted for 33% of Australia’s renewable energy in 2017. That’s amazing!

Ocean power

The ocean can generate electricity in a few ways: tidal power, wave power or ocean thermal energy. Here, we will focus on wave power.

Wave power is still quite new in Australia, but research has shown that our southern coastline could be a great resource as it has deep water with consistently large waves.

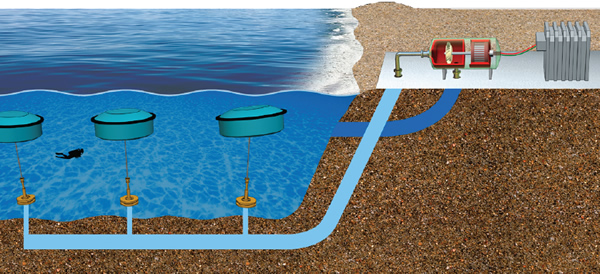

To generate power, large ‘floats’ are tied to the ocean floor. The motion of the waves causes the floats to move up and down which powers a pump. The pump moves pressurised water along pipes to the land where there is a turbine which runs a generator. The generator produces electricity.

Perhaps the power of the ocean will soon be a big contributor to Australia’s renewable energy. There’s a lot of water out there!